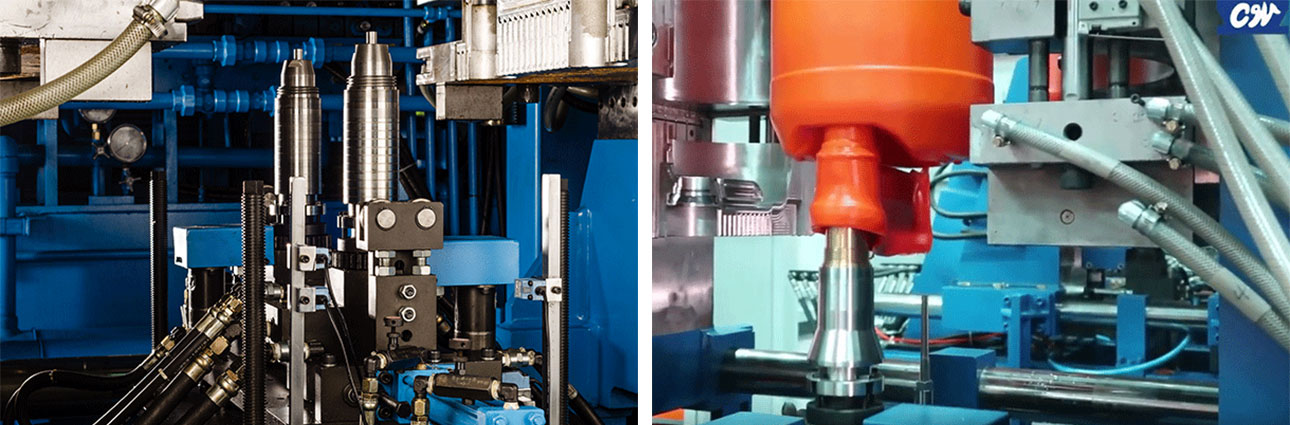

Inner thread Unscrew Function for Extrusion Blow Molding Applications

Many plastic containers have a design consisting of an outer thread neck and a cap or lid screwed on the thread to seal them. This outer thread can be easily formed by using a split mold. However, in the case of an inner thread, a different approach must be used. Chen Way Machinery’s customers regularly require extrusion blow molding machines with the ability to make an inner thread neck in their products. Therefore, an unscrew function needs to be added to the blowing unit to properly form the threads inside the product's neck.

How does this unscrew function for extrusion blow molding applications work?

For the unscrew function to be integrated into the blow pin unit, it must be a bottom blow unit. The blow pin will include the neck thread's design, which will be molded into the plastic container during the blowing process. Then, after the mold slightly opens, the blow pin will rotate inside the product's neck while slowly moving downwards. This action will allow the inner threads to be perfectly formed during the cycle time.

Which are the applications of the inner thread unscrew function mechanism?

The most common uses of unscrew function are for the 10L to 30L HDPE inner thread

Read also: Chen Way, the leader in blow molding machinery industry

Chen Way Machinery: jerry can making machine with unscrew function for inner thread video

A second example of the inner thread unscrew function for extrusion blow molding applications, is the narrow mouth HDPE plastic drum, which sizes commonly range from 200L to 250L single and double L ring drum. For making these L-ring HDPE drums with 2 necks and inner threads, an Accumulator Die Head Blow Molding Machine with bottom blow unit and inner thread unscrew function is needed.

Read more about Plastic Drums and Plastic Drum Machines

Chen Way Machinery: 200L Double L-ring drum

machine with unscrew function for inner thread video

How to contact Chen Way Machinery

Getting in touch with Chen Way Machinery is simple. We acknowledge the importance of making ourselves readily available to our customers and therefore promptly check our communication channels. In order to request further information or obtain a quotation for our blow molding machines, you can send us an inquiry.

You can also stay updated about Chen Way Machinery’s news, machine videos, and more through:

TOP