Top 3 Plastic Floats Made by Blow Molding

- Plastic solar floats for PV systems

- Plastic floats for docks

- Plastic floats for aquaculture fish farming

1. Blow molding of plastic floats for PV systems

A common application made by float blow molding machines is HDPE floats

for photovoltaic (PV) systems. These systems are power generation systems that

consist of PV modules mounted on water surfaces by using plastic floating

platforms that are lightweight, cost-effective, and which may also vary in size

and shape in order to fit the requirements of the manufacturer.

In the case of PV systems, several solar floats are combined to form a

giant pontoon. These solar floats are usually made of HDPE, a plastic that is

known due to its tensile strength, UV, and corrosion

resistance.

2.

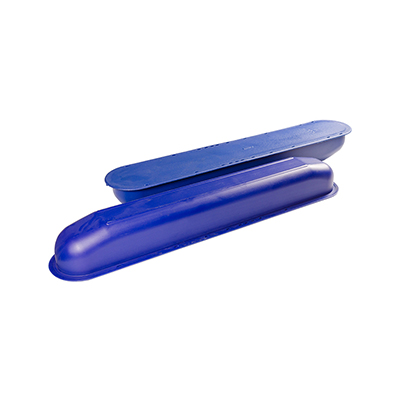

Blow molding of plastic floats for floating docks

Floating docks are incredibly useful because they are adaptable,

durable, and easy to maintain compared to other docking types. This kind of

dock floats on top of the water instead of being attached to the surface

beneath it, meaning that as the water moves and levels fluctuate, so does

it. These structures are commonly made of polyethylene, so they will not

warp, rust, or dent, and can withstand severe weather conditions with the right

anchoring hardware. Another benefit of plastic floats made with polyethylene is

that this material allows docks to stay cool and burn-free even during hot

summers. Moreover, by manufacturing floats with a textured surface which makes

them slip-resistant and easy to maintain a grip, they become an incredibly safe

option for everyone.

Float blow molding can produce plastic floats that vary in size and

shape and can also be customized to create unique layouts. The resulting

plastic floating docks are made for residential, commercial, or industrial

purposes and are often preferred because they can be relocated, altered, or

even extended. Moreover, they are safe and stable for anyone walking or making

use of them.

3. Blow

molding of plastic floats for aquaculture fish farming

Another very popular application of blow molding for large products is the molding of Paddle Wheel Aerator Floats and Gear Box Covers for aquaculture. These floats are used in fish farming for giving the fish the oxygen they need from the environment for breathing. With a paddlewheel aerator, water currents are created, which is an environment that attracts fish and shrimps.

Chen Way Machinery: float blow molding machine for

aquaculture fish farming

Float blow molding machine key features

Some key features of blow molding machines that can guarantee the manufacture of high-quality floats are:

- Accumulator Die Head:

Float blow molding machines equipped with an accumulator head designed with two heart-shaped flow channels, weld line-free can increase the strength of the hollow plastic products.

- Special Clamping Unit:

This unit exerts an equally distributed clamping force along the vertically long plates which allows the paddle aerator plastic float and gearbox cover to be perfectly shaped without having any air leakage during formation.

- Injection Speed:

Float blow molding machines should also combine an adequate injection speed with a parison control unit -programmed to achieve an even thickness distribution- in order to manufacture aerator floats that are stable and can perform as required when put into water.

- Post-cooling unit:

Post Cooling units help to complete the formation of the paddlewheel aerator floats.

The advantages of using a post-cooling unit for paddlewheel aerator plastic floats are:

For years, Chen Way Machinery has manufactured float-making machines for its customers all around the globe. These blow molding machines are capable of producing customized plastic floats of all types that are very high-quality and durable. If you would like to request a quotation or more information about Chen Way’s blow molding machines to produce plastic floats, contact us now!

TOP